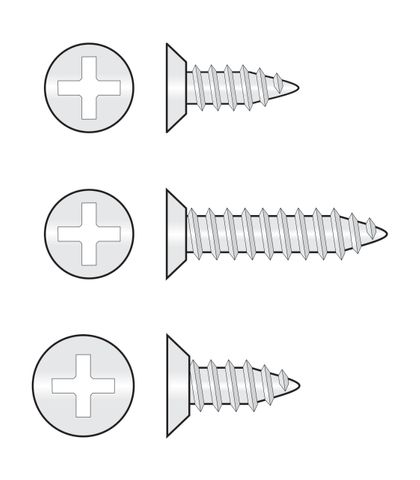

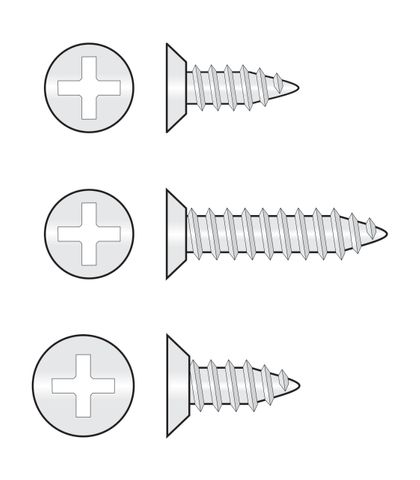

172010 Stainless Steel Self-Tapping - Countersunk Undercut Head

Recommended for fixing into timber or sheet metal in corrosive environments or where a long life fastener is required. Designed primarily for fixing hinges to metal substrates the undercut head allows the screw head to sit flush with the surface of the hinge. Made from 300 Series Stainless Steel provides a long life, aesthetically pleasing, bright shiny silver finish with high hygienic benefits. If fastening into metal ensure it is compatible with Stainless Steel Self-Tapping screws.

• The undercut head allows for the screw to finish flush with the surface of hinges when they are being fixed to solid metal substrates

• An economical general purpose stainless steel fastener which can perform as a self-drilling screw in medium density timbers and very popular when used as a self tapping screw for Sheetmetal applications

• High Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Aesthetic appearance

• Available in a wide range of sizes and lengths

• An economical general purpose stainless steel fastener which can perform as a self-drilling screw in medium density timbers and very popular when used as a self tapping screw for Sheetmetal applications

• High Corrosion Resistance

• High Fire and Heat Resistance - Retains strength under harsh and extreme temperature conditions

• Hygienic- Easy to clean and sanitise

• Impact Resistance and strength - extremely tough and highly durable material with high impact resistance

• Aesthetic appearance

• Available in a wide range of sizes and lengths

1/ Ensure the correct driver tool is fitted to your power drill or screw driver. Can also be driven by hand screw driver.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ If necessary push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is approximately 800~1,000 r.p.m.

Note:-

Hardwoods may require a pilot hole to be pre-drilled as this will assist the screw in tapping a thread whilst reducing timber splitting and driving torque.

Sheet metal must be pre-drilled with a pilot hole.

For information on the correct size pilot hole to drill refer to our Technical data section for Self Tapping Screws.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ If necessary push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, constant pressure until the screw has drilled and fastened.

Recommended Driving speed is approximately 800~1,000 r.p.m.

Note:-

Hardwoods may require a pilot hole to be pre-drilled as this will assist the screw in tapping a thread whilst reducing timber splitting and driving torque.

Sheet metal must be pre-drilled with a pilot hole.

For information on the correct size pilot hole to drill refer to our Technical data section for Self Tapping Screws.

• Undercut heads are ideal for fixing hinges to metal surfaces or thin countersunk metal members to metal substrates in flyscreens etc.,

• Can be used for fixing metal beadings around windows to metal frames

• Ideally suited for fastening any thin f

• Can be used for fixing metal beadings around windows to metal frames

• Ideally suited for fastening any thin f

| Size | Pack Type | 480 Y Material | 490 Y Description/Features | 520 Y Thread Length (TL) | 530 Y Driver Tool | Code |

|---|---|---|---|---|---|---|

| 8g x 1/2" (12mm) |

|

|||||

| 10g x 1/2" (12mm) #10Hd |

|

|||||

| 10g x 1/2" (12mm) #8Hd |

|

|||||

| 10g x 3/4" (20mm) #8Hd |

|