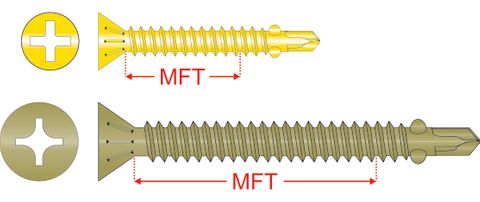

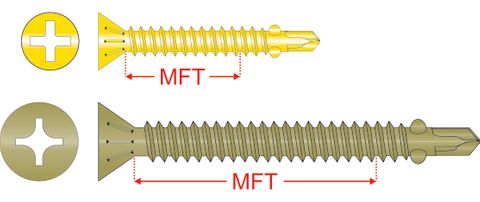

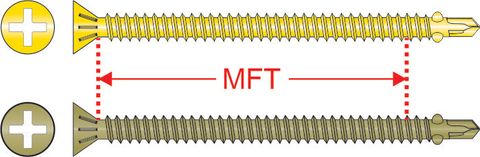

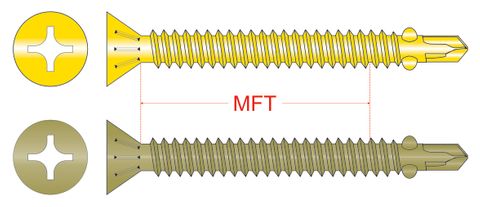

120330 SteelMates® - Countersunk Rib Wing

Designed for fixing timber to meta. Featuring Wings which counterbore a clearance hole in the timber allowing the drill point to drill the timber without threads engaging in it. This prevents timber ride up &/or splitting and drill point damage. The wings snap off when they contact the metal allowing the thread to engage and the ribbed head to self countersink into the timber. Popular sizes are also available in Collated coils. NOT recommended for fixing in decking applications.

• Eliminates the need to drill a clearance hole through the timber being attached

• Fast drilling and easy to use

• Available in Zinc Yellow plating for internal use and MGZA or EP+ Gold for extra corrosion protection or for external use. Always use EP+ or MGZA for external use. When fixing treated timbers only EP+ coating is to be used.

• Complies with AS3566.1 & 2

• Fast drilling and easy to use

• Available in Zinc Yellow plating for internal use and MGZA or EP+ Gold for extra corrosion protection or for external use. Always use EP+ or MGZA for external use. When fixing treated timbers only EP+ coating is to be used.

• Complies with AS3566.1 & 2

1/ Ensure the correct driver tool is fitted to your power drill or screw driver.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ Push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, low pressure. Do not force the wings through the timber or they may snap prematurely. Once the drill point contacts the steel substrate instantly apply extra pressure to ensure the wings snap off when they contact the steel.

5/ Maintain pressure until the screw has fastened.

Recommended Driving speed is approximately 2,000 r.p.m.

2/ Place the screw on the driver tool and position it onto the materials being fastened.

3/ Push sharply to create a centre mark and to prevent screw wander.

4/ Squeeze trigger and maintain steady, low pressure. Do not force the wings through the timber or they may snap prematurely. Once the drill point contacts the steel substrate instantly apply extra pressure to ensure the wings snap off when they contact the steel.

5/ Maintain pressure until the screw has fastened.

Recommended Driving speed is approximately 2,000 r.p.m.

• A range of sizes are available from 6g to 14g for a multitude of applications including using 6g for skirtings, architraves, window reveals, door jambs, etc, 8g for fibre cement board, 8g & 10g for Subfloors & decking applications up to 14g for timbe

| Size | Coating | Pack Type | 500 Y Drilling Capacity in Steel | 520 Y Thread Length (TL) | 530 Y Driver Tool | 580 Y Max. Fixture Thickness | Code |

|---|---|---|---|---|---|---|---|

| 6g-20 x 30mm |

|

||||||

| 6g-20 x 50mm |

|

||||||

| 8g-18 x 22mm |

|

||||||

| 8g-18 x 32mm |

|

||||||

| 8g-18 x 35mm |

|

||||||

| 8g-18 x 40mm |

|

||||||

| 10g-16 x 30mm |

|

||||||

| 10g-16 x 35mm |

|

||||||

| 10g-16 x 40mm |

|

||||||

| 10g-16 x 45mm |

|

||||||

| 10g-16 x 50mm |

|

||||||

| 10g-16 x 60mm |

|

||||||

| 10g-16 x 70mm |

|

||||||

| 14g-14 x 60mm |

|

||||||

| 14g-14 x 85mm |

|